Types of Welding Joints and Their Uses

7 October 2021

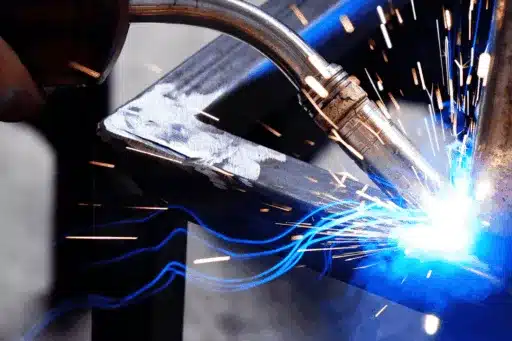

Welding joints are crucial in ensuring the strength and integrity of welded structures. Whether you are working on a pipe, a metal frame, or any other welding project, choosing the right type of welding joint is essential. Here’s a breakdown of the most common types of welding joints, their applications, and benefits.

A joint is defined by the American Welding Society (AWS) as “the manner in which materials fit together.” Welding has a wide range of applications, and different jobs require various types of welds and joints.

Welding is a complex skill that involves patience, attention to precision, and creativity. Welders must have a thorough awareness of the numerous techniques and practices utilized in the industry, including welding joint types to accomplish their jobs well.

As a weld cleaner company, TIG Brush outlines the five most common welding joint types here. Each type is designed to withstand the forces and needs of particular applications.

1. Butt Joint Welding

A square grove weld is another name for a butt joint weld. It’s the simplest and, by far, the most common type of weld. It is made up of two flat pieces that are parallel to each other. This joint type is often used in industries like construction, marine, and automotive manufacturing for its ability to deliver high-quality, strong joints.

It is also used for flanges, valves, fittings, and other equipment because it is the internationally accepted way for joining a pipe to itself. It’s a really cost-effective solution.

Welding Styles Used to Create Butt Joints:

- Flare-V-groove weld

- Flare-bevel-groove weld

- J, U, and V-groove weld

- Bevel-groove weld

- Square-groove weld

A square butt joint can commonly be used to achieve full penetration welds. When welding on a thick plate or pipe, it’s nearly impossible to attain 100 percent penetration without using some sort of groove.

Common Issues:

Burn through, cracking, porosity, and inadequate penetration are the most common faults in butt joints. However, by changing welding factors such as groove shape, layering, and gap width, these can be avoided.

If you’re looking to ensure a clean, precise weld and avoid common defects, consider using specialized weld cleaning machines. These tools are designed to help remove oxidation and enhance the quality of your joints for an efficient solution to weld finishing.

2. Tee Joint Welding

A tee joint welding forms when two pieces meet at a 90-degree angle. The edges of a plate or component form a ‘T’ shape when they come together in the middle. Tee joints are a sort of fillet weld that can be made by welding a tube or pipe to a base plate.

This type of weld requires constant inspection for effective penetration into the weld’s roof.

Welding Styles Used to Create Tee Joints:

- Fillet, slot, and plug weld

- J-groove weld

- Flare bevel-groove weld

- Melt-through weld

- Bevel-groove weld

Challenge:

Lamellar tearing is a typical problem with tee joints, which develops due to the joint’s limitation. Welders will frequently insert a stopper to prevent joint distortions.

Butt Joint Weld

Tee Joint Weld

3. Corner Joint Welding

Corner welding joints resemble tee welding joints. The only difference is the positioning of the metal. It’s in the middle of a tee junction, whereas corner joints meet in the corner in a closed or open manner, creating an ‘L’ shape.

These joints are popular in the sheet metal industry, where they’re used to make frames, boxes, and other items. An outside corner junction can be fitted in two ways: either a V-groove or a square butt joint.

Welding Styles Used to Create Corner Joints:

- Spot, edge, and fillet weld

- V, J, and U-groove weld

- Bevel-groove weld

- Corner-flange weld

- Flare-V-groove weld

- Square-groove or butt weld

Applications in the Sheet Metal Industry:

These joints are popular in the sheet metal industry, where they’re used to make frames, boxes, and other items.

4. Lap Joint Welding

The butt joint is a modified version of the lap welding joint or vice versa. They’re formed when two pieces of metal are stacked in an overlapping pattern on top of each other. They’re most typically used to connect two parts of different thicknesses.

Lap joints are usually used for sheet metal and are rarely used on thicker materials. Corrosion or lamellar tearing due to overlapping materials are the potential downsides of this type of welding joint. However, as with anything else, this may be avoided by utilizing proper technique and modifying variables, such as amps and volts, as needed.

Welding styles used to create butt joints include:

- Plug, slot, and spot weld

- J-groove weld

- Flare-bevel groove weld

- Bevel-groove weld

Common Issues:

Corrosion or lamellar tearing due to overlapping materials are the potential downsides of this type of welding joint. However, as with anything else, this may be avoided by utilizing proper technique and modifying variables, such as amps and volts, as needed.

5. Edge Joint Welding

The metal surfaces are joined together in an edge joint to ensure that the edges are even. Bending one or both plates at an angle can help to form them. The purpose of a weld joint is to bind pieces together and distribute stresses.

Forces That Cause Stress in Welded Joints:

- Tensile

- Compression

- Bending

- Torsion

- Shear forces

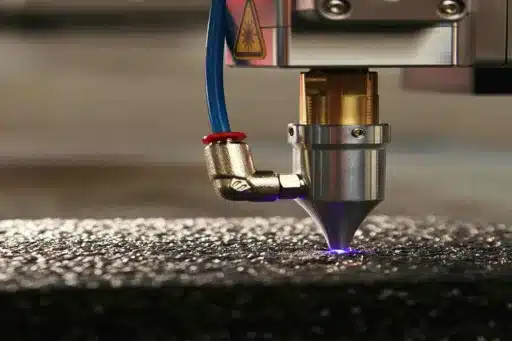

The welding procedure that will be used has a significant impact on the joint design that will be chosen. Each welding technique has its own set of properties that influence how well it performs. The welds used on various joint designs are additionally affected by the rate of travel, deposition rate, penetration, and heat input.

Welding Styles Used for Edge Joints:

- Bevel-groove weld

- Corner-flange weld

- Square-groove weld

- Edge-flange weld

- U, J, and V-groove weld

Lap Joint Weld

Edge Joint Weld

Need a Weld Cleaner?

Choosing the right welding joint is vital to ensuring the strength, durability, and efficiency of your project. Whether you’re working with butt welds, tee welds, corner welds, lap welds, or edge welds, each joint type offers distinct benefits for specific applications. Understanding these joints and their uses can significantly improve the quality of your welding projects.

Ready to take your welding to the next level? Explore TIG Brush’s range of welding solutions designed to help you achieve precision, strength, and long-lasting results.

FAQs

1. What are the different types of welding joints?

The five most common types of welding joints are butt joints, tee joints, corner joints, lap joints, and edge joints. Each type is used for specific applications, depending on factors such as the materials being joined, the welding position, and the forces the joint will need to withstand.

2. How do I choose the right welding joint for my project?

Choosing the right welding joint depends on factors like the thickness of the materials, the desired strength of the joint, and the type of load it will endure. For example, butt joints are often used for joining pipes, while corner joints are ideal for sheet metal work. Understanding the properties of each joint type is essential for making the best choice for your project.

3. What are the common issues with welding joints?

Common issues with welding joints include burn-through, cracking, porosity, and inadequate penetration. These problems can often be avoided by adjusting factors like the groove shape, layering, gap width, and the welding technique. Proper weld cleaning can also reduce defects and improve the overall quality of your joints.

4. How can I improve the quality of my welds?

To improve the quality of your welds, ensure that you use the correct joint type for your materials and applications. Additionally, investing in weld cleaning machines can help remove oxidation and contaminants from your welds, resulting in cleaner, stronger, and more durable joints. TIG Brush’s welding solutions are designed to enhance the precision and finish of your welds.

5. When should I use lap joints instead of butt joints?

Lap joints are typically used when joining two pieces of metal with different thicknesses, making them ideal for sheet metal applications. In contrast, butt joints are more common for welding thicker materials and achieving full penetration welds. Each joint type has its own benefits, so choose based on the material thickness and the structural requirements of your project.