Comparing TIG Brush’s Weld Cleaning Products

27 October 2025

When it comes to stainless steel work, weld finishing is often the most laborious (and error-prone) stage. That’s why a robust weld cleaning system can make all the difference in quality, speed, and safety.

In this article, we’ll walk through TIG Brush’s full product lineup and compare their features, strengths, and ideal use cases. The goal? To help you choose the right machine for your welding needs.

The industry-leading solution for weld cleaning and passivation, the trusted TIG Brush system is unmatched (from protecting and extending the life of metal surfaces to minimizing user effort and environmental impact). Get in touch today for more information.

Why Choose an Electrochemical Approach for Weld Cleaning?

Before diving into models, it’s useful to understand what sets TIG Brush apart.

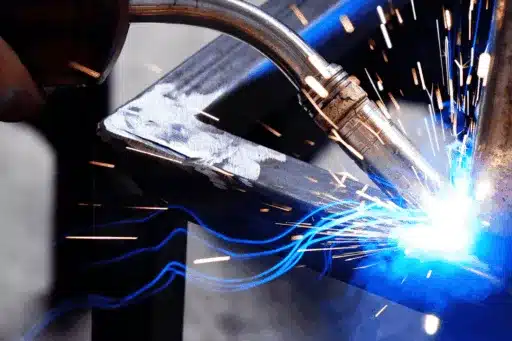

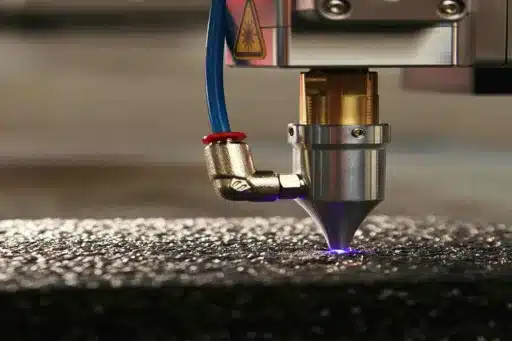

Instead of grinding, abrasive media, or highly corrosive pickling pastes, TIG Brush uses an electrochemical weld cleaning method. It combines mild electrolyte fluids, electrical current, and heat to remove heat tint, oxide layers, and discoloration while simultaneously passivating the stainless surface.

It offers many advantages:

- Safer for operators (as there’s no hydrofluoric or nitric acid)

- Cleaner, consistent finishes with less manual polishing

- Often faster overall than traditional methods

- Integrated passivation in one step

Of course, no one size fits all. TIG Brush currently offers four main models to suit different scales: 330, 440, 550, and 700. Below is a comparative look at each.

Models at a Glance

Model: TIG Brush 330

Ideal Use Case: Light and occasional welding, small shops

Key Strengths: Compact, portable, cost-effective, full passivation, IP65 rated

Limitations: Less power for tough or large welds

Model: TIG Brush 440

Ideal Use Case: Moderate use, small to medium fabrication

Key Strengths: Good balance of performance and price, multi-function (clean, polish, branding)

Limitations: May struggle with extremely heavy or heavily oxidized welds

Model: TIG Brush 550

Ideal Use Case: Mid to heavy workloads

Key Strengths: Built from the same design as the 700 series, but economically balanced

Limitations: More expensive; may be overkill for light tasks

Model: TIG Brush 700

Ideal Use Case: High output, industrial

Key Strengths: Maximum speed, power, capability for toughest jobs

Limitations: Most expensive; may require more training or care in use

Deep Dive into Each Model

TIG Brush 330

The 330 is designed as a purpose-built unit for weld cleaning and passivation, nothing else. It’s compact, bright in color (for visibility on shop floors), and can handle occasional stainless steel work.

Key features:

- 100% duty cycle (no forced cooling downtime).

- Dynamic Power Transfer automatically adjusts output based on brush condition and surface.

- IP65-rated housing makes the unit dust- and splash-resistant.

- Uses the Push-In Brush (PIB) system, which is corrosion-resistant and easy to replace.

This model is best for small shops, occasional field work, or where space and budget are limited. However, it’s not intended for heavy, continuous operation on large weldments.

TIG Brush 440

The 440 offers more flexibility without a dramatic cost jump. It’s ideal for fabricators who weld regularly but don’t yet face industrial volumes.

Key features:

- Up to 60 amps at 100% duty cycle.

- Offers not just cleaning/passivation, but also electropolishing and branding/etching modes.

- Dual-voltage TBE models can run on 110-240V, making them portable across different regions.

- Still retains the Push-In Brush interface and compatibility with all TIG Brush application tools.

If your shop sees occasional moderate to heavy welds but doesn’t yet justify a top-tier machine, the 440 is a compelling “sweet spot”. Just be cautious: under extremely heavy or oxidized welds, it may lag.

TIG Brush 550

The 550 bridges the gap between moderate and heavy. It leans on the architecture of the 700 series to bring more power without formally committing to the highest tier.

Key features:

- Better capability on dirtier, thicker welds than the 440.

- Maintains compatibility with the same TIG Brush fluids and application tools.

- Designed to deliver “mid-to-heavy” performance with a better price-performance ratio than stepping straight to the 700.

In short, when the 440 starts to show its limits, the 550 is often the right upgrade without jumping all the way to the 700 class.

TIG Brush 700

At the top of the line, the 700 series is built for heavy-duty, high-throughput operations. If you’re running an industrial fabrication shop, the 700 is the flagship.

Key features:

- Swift cleaning of both TIG and MIG welds (at least twice the speed of the nearest alternatives).

- Designed for continuous heavy-duty usage, large components, pipework, tanks, and structural weldment finishing.

- Same platform compatibility (fluids, brushes, and tools) as the rest of its siblings.

Its cost and complexity make it overkill for lighter shops, but for high-volume, demanding environments, it pays off in time saved and finish consistency.

Weld Cleaning Made Easy with TIG Brush

The beauty of the TIG Brush family is that they share core technology (Dynamic Power Transfer, push-in brushes, and fluid compatibility) while scaling performance across models. For anyone weighing their options, this alignment means you can choose the right tier without drastic changes to your workflow or consumables.

If you need help determining the most suitable model for your needs or would like to see the TIG Brush in action, please don’t hesitate to contact our expert team. We’re here to help.