Are Weld Cleaning Solutions Safe?

22 December 2025

Weld cleaning is an essential step in producing durable, hygienic, and visually consistent stainless steel. For fabricators across Australia and the United States, the question often comes down to one thing: are modern weld cleaning solutions actually safe to use?

Today, operators have more options than ever, ranging from mechanical cleaning to chemical pastes and electrochemical systems. Some of these approaches bring clear risks, while others offer safer and easier pathways to achieving a clean, stable finish.

This article explains how weld cleaning solutions work, where the risks usually come from, and why many workshops now choose safer electrochemical systems.

Key points

- Weld cleaning removes heat tint and contamination, which protects stainless steel from corrosion.

- Traditional methods like grinding, sandblasting, and harsh chemical pastes can create airborne hazards, inconsistent results, and rework.

- Modern weld cleaning solutions offer safer handling, reduced fumes, and a controlled application.

- Electrochemical systems provide a safer alternative for teams in Australia and the United States working across stainless fabrication.

- A demo can help teams understand the best option for their workflow.

What are weld cleaning solutions?

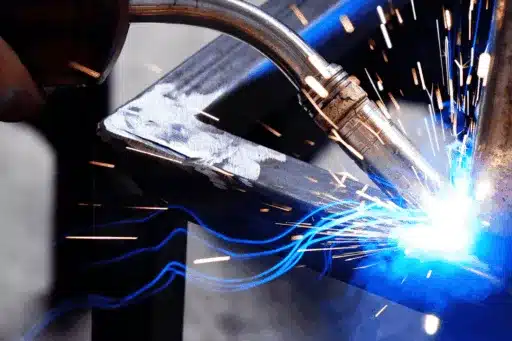

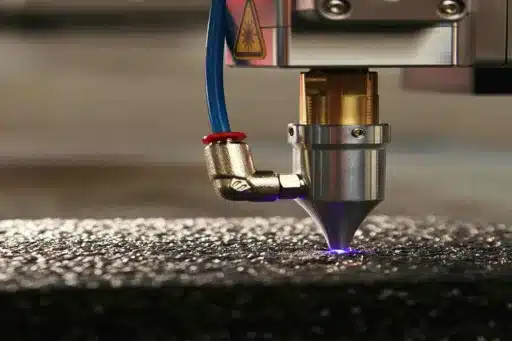

Weld cleaning solutions treat the heat tint and surface oxidation that form during TIG, MIG, MAG, Sub Arc, stick, and laser welding. These oxides must be removed so that the stainless surface remains clean, stable, and suitable for industrial use.

What are weld cleaning solutions?

Weld cleaning solutions treat the heat tint and surface oxidation that form during TIG, MIG, MAG, Sub Arc, stick, and laser welding. These oxides must be removed so that the stainless surface remains clean, stable, and suitable for industrial use.

In most stainless fabrication workflows, weld cleaning solutions work alongside tools or equipment designed to restore the surface after joining. Depending on the method, this can involve chemical reactions, abrasive removal, or a combination of both. Effective weld cleaning supports longevity, improves appearance, and keeps equipment ready for ongoing service.

Why safety matters in weld cleaning

Safety concerns often appear when teams rely on older weld cleaning methods. Mechanical cleaning, grinding, and sandblasting can release stainless steel dust and abrasive residue into the workspace. This can affect air quality and also risk damaging the stainless surface, which may lead to additional finishing or rework.

Chemical pastes present a different challenge. Some of these products have traditionally required caution because of their fume levels and the protective equipment needed for safe handling. They can also be difficult to control on complex parts, increasing the risk of over-application or surface damage.

Across industries like food and beverage, automotive manufacturing, energy equipment, and architectural fabrication, safety and consistency matter just as much as appearance. This is why many fabricators now look for weld cleaning options that simplify handling while supporting operators.

How modern weld cleaning solutions improve safety

Modern weld cleaning solutions are designed to reduce the risks associated with older processes. Low-fume formulations help maintain a safer workspace, and a controlled, surface-targeted reaction limits exposure for the operator. Because the process focuses only on the weld area, the surrounding stainless steel remains intact.

Compared with grinding or blasting, safer weld cleaning solutions also reduce airborne metal particles. This helps maintain cleaner working conditions, especially during repetitive cleaning tasks.

Many systems used in Australia and the United States integrate matched fluids with dedicated equipment. This pairing keeps the process predictable and easier for operators to learn.

You can read more about these systems in the TIG Brush weld cleaning blog.

Are electrochemical weld cleaning systems safer to use?

Electrochemical weld cleaning uses a brush-based application that delivers a controlled reaction on the weld surface. This approach reduces operator exposure and avoids the airborne dust associated with mechanical methods. It also limits the risks linked to harsh chemical pastes, because the fluids are applied in small amounts and used directly at the point of contact.

For stainless steel fabricators, OEMs, and maintenance teams, the benefit is a simpler, cleaner process that still produces a consistent finish. Because the method is easy to learn, teams can train new operators without the challenges linked to more hazardous approaches.

Across Australia and the United States, fabricators rely on electrochemical weld cleaning to support safe, efficient workflows while maintaining high surface standards.

Why do many workshops prefer TIG Brush style solutions?

Workshops that switch to electrochemical systems often highlight the simplicity of the process, the stability of the results, and the reduced need for rework. A brush-based workflow helps operators stay in control of the cleaning action, even on complex welds or tight geometries.

This method is suitable for a wide range of welding processes, including TIG, MIG, MAG, Sub Arc, stick, and laser welds. Maintenance teams working on stainless equipment and pipework also benefit from a process that is fast to set up and safe to use in varied environments.

When paired with matched fluids, these systems deliver a reliable cleaning action that supports both durability and appearance.

How to choose a safe weld cleaning solution

When selecting a weld cleaning approach, consider how the method interacts with both the operator and the stainless surface. A safe solution should minimise fume levels, avoid releasing airborne particles, and be easy for operators to control.

Training is another important point. Choose a method that supports clear, repeatable steps so that new and experienced welders achieve the same results. System-matched fluids can assist with predictable performance and reduce the chance of over-application.

If your team works across multiple sites or handles different grades of stainless steel, portable equipment can also support workflow efficiency.

See the Process in Action

If you would like to see how a safer weld cleaning approach could support your work, you can request a demo from the TIG Brush team.

A guided demonstration helps you understand how the process fits your workflow and the surfaces you manage.

Frequently Asked Questions

1. Are weld cleaning solutions safe for operators?

Modern weld cleaning solutions are designed to reduce common risks, including fume exposure and airborne particles. Low-fume formulations and controlled application support safer handling during routine finishing tasks.

2. Is electrochemical weld cleaning safer than grinding?

Electrochemical cleaning avoids the dust and abrasion produced during grinding. Because the reaction occurs only on the weld, the surrounding work area stays cleaner, and the surface remains protected.

3. Can weld cleaning solutions be used on food-grade stainless steel?

Yes, safer weld cleaning solutions are suitable for applications where hygiene and surface stability matter. They help remove heat tint and restore a clean stainless surface without introducing abrasive damage.

4. Do these solutions work across different welding processes?

Electrochemical weld cleaning suits TIG, MIG, MAG, Sub Arc, stick, and laser welds. The method scales well from small fabrications to larger components, making it a practical option for varied workshops.

5. How do I know which weld cleaning method is right for my team?

Consider factors such as operator safety, surface quality, training time, and workflow demands. A demonstration can help you assess whether electrochemical cleaning aligns with your equipment, part type,s and productivity goals.