Neutralizing After Weld Cleaning: Why It’s Critical and How to Do It Right

26 September 2025

In industrial welding, finishing a joint isn’t only about strength and appearance; it’s also about protection. After weld cleaning, neutralizing is a vital step that often gets overlooked.

Without it, chemical residues can linger, leading to staining, corrosion, or even structural weakness. From stainless steel pipelines in food production to offshore equipment in marine industries, neutralizing ensures surfaces are safe, stable, and ready for long-term use.

This blog explores why neutralizing is critical after weld cleaning, how the process works, and the best practices to get it right across industries.

Trusted by professionals across demanding industries worldwide, Enistech continues to lead the way in stainless steel surface treatment. TIG Brush is their industry-leading solution for stainless steel weld cleaning and passivation; contact us today to learn more.

Why Neutralizing Matters

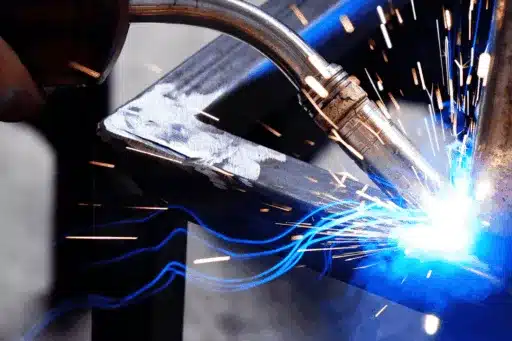

Weld cleaning often involves acidic solutions or electrochemical processes to remove oxides, heat tint, and contamination from stainless steel surfaces. While these steps restore corrosion resistance, they can leave behind acidic residues.

If not neutralized, those residues may:

- Continue reacting with the metal surface, causing white streaks or marks

- Increase the risk of pitting and corrosion over time

- Compromise the appearance and hygiene of the surface (which is especially problematic in food and beverage or pharmaceutical applications)

- Lead to premature equipment wear, increasing maintenance and replacement costs

Neutralizing restores pH balance, halts further reactions, and leaves surfaces chemically stable. In short, it locks in the benefits of weld cleaning.

Neutralizing Across Industries

1. Food and Beverage

Cleanliness and safety are paramount in the food and beverage sector. After weld cleaning on stainless steel equipment, neutralization ensures no acidic residues remain that could contaminate food or compromise hygiene. By restoring the balance, neutralizing supports both regulatory compliance and product shelf life.

2. Marine

It should be no surprise that saltwater environments are harsh on metals. Without neutralizing, welds cleaned with acidic solutions can corrode more quickly in marine settings. Proper neutralization protects ship hulls, offshore platforms, and other structures from corrosive attack, which can save on costly repairs.

3. Building and Construction

Construction projects often rely on stainless steel for its strength and durability. Neutralizing after weld cleaning helps maintain that durability by preventing rust and corrosion on exposed joints. This step extends the lifespan of critical infrastructure.

4. Oil and Gas

In oil and gas applications, pipelines and equipment operate under demanding conditions. Acid residues from weld cleaning can accelerate corrosion or scaling if not neutralized, which increases the risk of leaks or failures. Neutralization, on the other hand, safeguards operational integrity and reduces environmental risk.

The Chemistry of Neutralization

At the heart of it, neutralization is an acid-base reaction. Any remaining acidic cleaning residue combines with a basic neutralizing agent to form water and a stable salt. The result is a surface with a safe, neutral pH.

In stainless steel weld cleaning, this reaction is essential to stop further chemical attack and prepare the surface for its natural protective chromium oxide layer to reform.

Best Practices for Neutralizing After Weld Cleaning

Use these tips and best practices to ensure that neutralization is successful:

- Wipe excess cleaning fluid first. Remove as much of the acidic cleaning solution as possible before applying the neutralizer.

- Apply generously. Cover the weld area thoroughly with neutralizing fluid; don’t just dab it on lightly.

- Allow time for reaction. Wait until any bubbling or fizzing subsides, as this is a sign that the acid has been neutralized.

- Rinse thoroughly. Wash the surface with clean water to remove any remaining salts.

- Dry completely. Thorough drying supports the reformation of the passive chromium oxide film that gives stainless steel its corrosion resistance.

Skipping or rushing any of these steps can reduce the effectiveness of neutralization and increase the risk of later corrosion or staining.

Benefits of Proper Neutralizing

Regardless of your industry, correct neutralization offers many benefits, including:

- Enhanced corrosion resistance, as it prevents pitting and rust formation.

- Better surface appearance, as it avoids unsightly white marks and other imperfections.

- Compliance with industry standards, which is crucial for food and beverage in particular.

- Extended equipment lifespan, as surfaces last longer, and this saves you on costs.

- Safer work environments, as it eliminates residual acids that can harm workers or downstream processes.

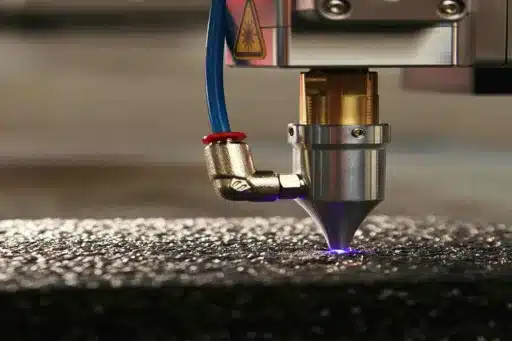

Make Neutralizing Easier with TIG Brush

Neutralizing after weld cleaning is a critical safeguard for stainless steel surfaces across industries. From food safety to marine durability and construction strength to oil and gas resilience, proper neutralization ensures welded joints remain strong, clean, and corrosion-resistant.

By following our best practices (including removing residues, applying neutralizer generously, rinsing, and drying correctly), you can ensure your welds are protected in the long term.

With solutions like those provided by TIG Brush, neutralization becomes a simple, reliable step in the cleaning workflow. Want to learn more or see it in action? Contact our team today.