Pickling Paste vs. Electrolytic Weld Cleaning: Safety, Results, and Compliance

16 August 2025

Weld cleaning is crucial for preventing contamination and corrosion. It also ensures proper hygiene for equipment in the food and beverage industry. While weld cleaning is a clear standout in terms of weld quality and longevity, the challenge for many professionals is choosing between modern electrolytic cleaning and more traditional pickling paste.

This article takes a closer look at both weld cleaning methods in terms of their safety, the results they generate, and their compliance with strict industry standards. We hope to clear up some of the common misconceptions, allowing you to make an informed decision.

TIG Brush is the industry-leading solution for stainless steel weld cleaning and passivation. Developed by Enistech, it combines the power of heat, electricity, and proprietary chemistry to deliver unmatched performance, safety, and efficiency. Contact us today to request a demonstration.

Pickling paste is a chemical cleaning agent (typically a gel or paste) used in stainless steel welding to remove discolouration and corrosion. It’s made from a mixture of hydrofluoric acid and nitric acid (both of which are highly corrosive), along with surfactants and inhibitors.

It’s applied to the weld area, left for some time, and then rinsed with clean water. Careful handling and proper safety precautions are essential.

What is Pickling Paste?

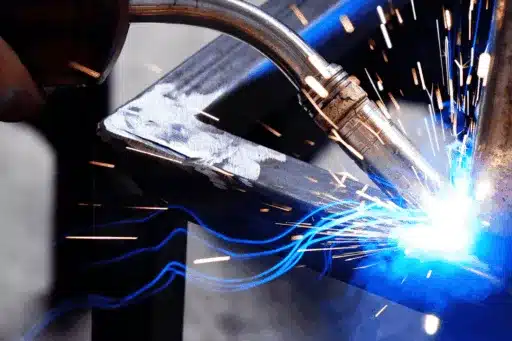

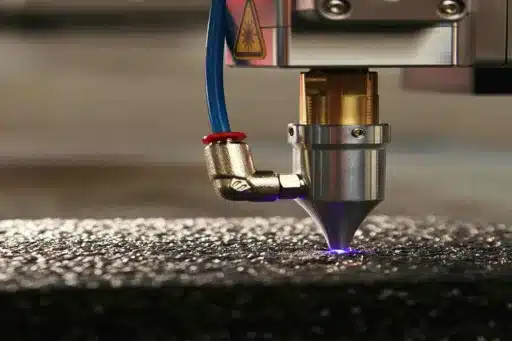

Electrolytic weld cleaning is a method that uses electricity and specialised electrolytic fluids to remove impurities, heat tint, and discolouration from stainless steel weld joints. It can also be used with other metals that are susceptible to discolouration.

It involves applying a low-voltage electrical current and a conductive electrolyte solution to the area, which creates a chemical reaction that cleans and passivates the surface.

Pickling paste is a chemical cleaning agent (typically a gel or paste) used in stainless steel welding to remove discolouration and corrosion. It’s made from a mixture of hydrofluoric acid and nitric acid (both of which are highly corrosive), along with surfactants and inhibitors.

It’s applied to the weld area, left for some time, and then rinsed with clean water. Careful handling and proper safety precautions are essential.

What is Electrolytic Weld Cleaning?

Electrolytic weld cleaning is a method that uses electricity and specialised electrolytic fluids to remove impurities, heat tint, and discolouration from stainless steel weld joints. It can also be used with other metals that are susceptible to discolouration.

It involves applying a low-voltage electrical current and a conductive electrolyte solution to the area, which creates a chemical reaction that cleans and passivates the surface.

Pickling Paste vs. Electrolytic Cleaning: Safety

Safety is a key concern when choosing a weld cleaning method. This refers to the safety of the person performing the clean, along with the safety of those around them.

Pickling Paste

This product contains corrosive acids that, if not handled correctly, can cause severe skin burns, respiratory problems, and even long-term health issues. You must work in a well-ventilated area and wear personal protective equipment (PPE), including gloves, eye protection, and respiratory protection.

Electrolytic Cleaning

This method is generally considered safer, as it uses only a mild phosphorus or citric acid-based solution. While basic PPE (like gloves and eye protection) should be worn, it doesn’t require the extensive measures that pickling paste does. Fumes are often minimal, although some systems do emit some steam vapour.

Pickling Paste vs. Electrolytic Cleaning: Results

For many professionals, the results generated are key in choosing a weld cleaning method. After all, you want to invest in the product that is going to offer the best possible outcome.

Pickling Paste

While this product is successful in dissolving the surface oxides of stainless steel to remove weld discolouration, it can result in a dull, matte grey finish. Additional steps (like mechanical polishing) may be required to restore the desired surface finish. This can add even more steps to the process, drawing it out, as well as increase the associated costs.

Electrolytic Cleaning

This process provides a cleaner, brighter finish without significantly altering the surface of the stainless steel. It can achieve both cleaning and passivation in a single step, which eliminates the need for separate passivation processes. Some older or cheaper electrolytic machines, however, may lack the power needed to achieve optimal results.

Pickling Paste vs. Electrolytic Cleaning: Compliance

Finally, ensuring that your chosen weld cleaning method complies with the industry’s strict standards is essential. Failure to comply could result in a serious accident, damage to your welds, and costly fines.

Pickling Paste

As this product requires careful handling, storage, and disposal of the hazardous chemicals involved, it may be necessary to obtain permits for its use. Wastewater from the rinsing process must also be collected and treated before you can dispose of it, which adds time.

Electrolytic Cleaning

This process is generally considered more environmentally friendly because it uses milder chemicals and reduces waste. It also offers better control over the cleaning process, which minimises the risk of overprocessing or damage.

The Winner? Electrolytic Cleaning Cannot be Beat

While both methods can achieve weld cleaning and passivation, electrolytic cleaning offers a safer, faster, and potentially more cost-effective solution compared to pickling paste. By removing impurities, it can also help to prevent future corrosion of the welded area (a significant advantage for many industries).

If you’re interested in learning more about electrolytic cleaning or would like to see one of the TIG Brush weld cleaners in action, get in touch with our helpful team. We’d love to take you through the process and provide a demonstration of our solution.