Electrolytic Weld Cleaning – The Fastest and Safest Way to Clean Stainless Steel Welds

10 February 2021

If you have been struggling with post-weld cleaning, then electrolytic weld cleaning could be the solution you’ve been searching for!

Cleaning welds manually may appear to be the cheapest and most affordable way to clean your welds, but it’s far from the most effective. Electrochemical weld cleaning is a process used in the manufacturing industry to remove post-weld impurities such as heat tint, discoloration, and surface rust using an electrical current and electrolytic fluids.

One of the most common uses for electrolytic weld cleaning is to prevent corrosion in stainless steel welded joints as well as to remove discoloration and heat tint.

In the following article, we’ll take a closer look at electrolytic weld cleaning and how it compares with other cleaning processes.

Why is it necessary to clean welds?

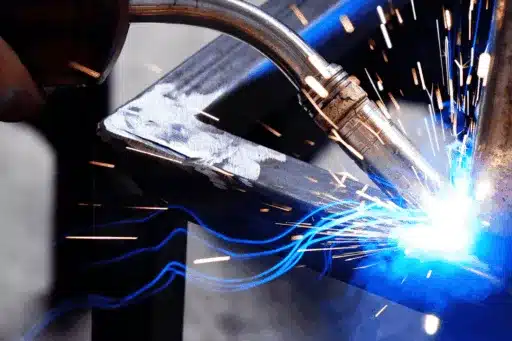

After TIG, MIG, and other welding processes have been used, cleaning of the welded area is essential to increase the life expectancy and corrosion resistance of a welded joint. Cross-contamination and rust are two of the most common issues resulting from the welding process.

Other issues, such as discoloration and heat tint, can also be a cosmetic issue. However, many of these issues can be corrected with cleaning processes such as electrolytic weld cleaning.

What are some of the causes of corrosion in metal?

It’s because of this that the process of electrolytic weld cleaning of stainless steel is so essential. It not only assists with preserving the strength of the material, but it also increases durability and the finished appearance of the welded joint.

Different types of weld cleaning processes?

When it comes to weld cleaning processes, you have three options: mechanical weld cleaning, chemical weld cleaning, and electrolytic weld cleaning. In this section, we’ll take a closer look at each of the three options and some of the advantages and disadvantages of each cleaning method.

- Mechanical weld cleaning – Mechanical weld cleaning processes include tools like grinders and sanders, and abrasives such as brushes and sandpaper. It’s a time-consuming process that rarely delivers an aesthetic or effective finish. Often damage caused to the surface during this process needs rectification later.

- Chemical weld cleaning – The most common chemical weld cleaning product used for weld cleaning is pickling paste. While somewhat effective, chemical cleaning is becoming increasingly unpopular and has some serious drawbacks, including:

- Health hazards – Pickling paste includes various acids such as sulfuric acid, nitric acid, and hydrofluoric acid, which can all be extremely dangerous, especially in combination.

- Ease of use – Pickling paste requires training, processes, and personal protective equipment and shouldn’t be used by inexperienced people.

- Environmental impact – Health effects on people aren’t the only risk when using pickling paste. Environmental impacts, such as air and water pollution, also need serious consideration.

- Electrolytic weld cleaning – While it may be one of the newest methods of cleaning welds, electrolytic weld cleaning for stainless steel and other metals is quickly gaining popularity worldwide. Not only is it considered one of the fastest ways to clean welded joints, but many experienced welders also consider it the most convenient and effective. In the next section we’ll explain the process and how it is being used to clean welded materials throughout the manufacturing industry.

How does the electrolytic weld cleaning process work?

The electrolytic weld cleaning process is simple, fast, and effective.

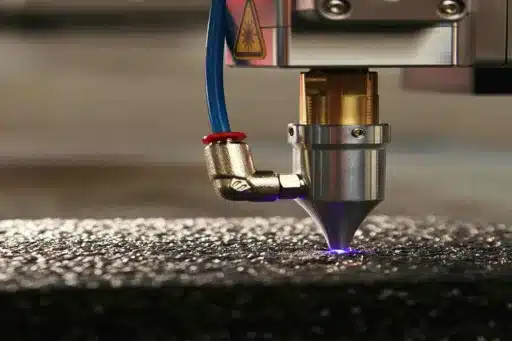

Using a conductive weld cleaning brush, a mild electrolytic cleaning fluid is applied to the welded joint or surface of the metal. Electric current is used to accelerate the cleaning and passivation process.

Some of the benefits of using this brushing process include:

- On-site Equipment – Instead of having to transport your newly finished work to another facility for cleaning or polishing, the brush process allows the process to be conducted in-premises for an immediate low-risk result.

- Greater flexibility – The portable aspect of a brush setup allows greater flexibility no matter when and where it’s used. There are larger electrolytic weld cleaning options, but they require large baths with heavy current supplies, and are particularly unsuitable for field or onsite use.

- One-step process – When using pickling paste, a separate passivation process is required after the pickling is complete. However, with the brush system the passivation occurs immediately – a second step it not required. A third re-finishing step is also not needed in order to remove etching marks from pickling paste or scratching from mechanical cleaning.

- Surface Treatment – When you submerge parts or components in a bath, you have no choice but to treat the entire component. With a brush application, you can choose which areas of the metal that you want to be treated, providing a more precise and targeted treatment.

- Affordability – The initial and running costs of manual electrolytic weld cleaning is minimal. However, large baths require a large initial investment either in the equipment itself or in setup costs, which is not cost-effective for many small to medium businesses.

It’s no surprise that workshops worldwide and across the country are moving away from pickling paste and embracing the TIG Brush for their electrolytic weld cleaning of stainless steel and other components. For many stainless steel fabrications, the final visual aspect and aesthetics of the welds are extremely important. Applications such as medical components and food preparation areas require welds to be completely cleaned and look immaculate. The TIG Brush has the required certification to be used in these applications.

Electrolytic weld cleaning – Conclusion

While the electrolytic weld cleaning process may initially seem daunting, you’ll quickly get the hang of it. Within minutes, you’ll be left wondering why it took you so long to make the change! If you have any questions about electrolytic weld cleaning or how the TIG Brush could change the way your workshop cleans welds, then please don’t hesitate to reach out and contact us directly.

If you would like more information on what we have discussed, feel free to reach out to us.