Enhancing Food Safety: Metal Marking Methods for the Food Industry

23 February 2024

Industry

The safety and traceability of products in food production is crucial. Metal marking solutions for food-grade applications are vital in achieving this goal. In this blog, let’s explore the importance of metal marking in the food production industry and the various methods used to mark metal parts in food processing.

Metal Marking in Food Production

Traceability

Metal marking facilitates traceability by allowing for the identification of components, equipment, and products throughout the production and distribution chain. This is particularly important for meeting regulatory requirements and ensuring food safety standards.

Cross-Contamination Prevention

Marking metal parts helps prevent cross-contamination, ensuring that equipment is used for its designated purpose and minimizing the risk of foodborne illnesses. Utilizing printing fluids for steel in food production ensures clear, durable, and traceable markings to meet strict industry standards for hygiene.

Metal Marking Methods

Metal Embossing

Metal embossing is a method that involves creating raised characters or designs on the surface of metal. This tactile marking method is durable and resistant to wear, making it suitable for applications in the food industry where hygiene and longevity are critical.

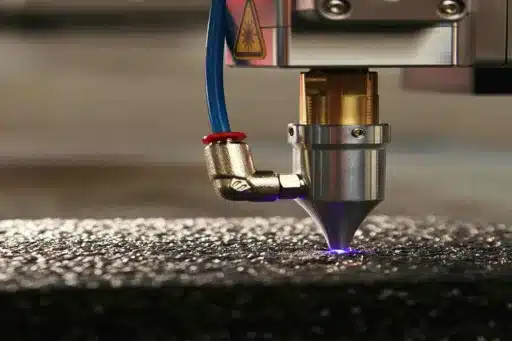

Laser Marking and Etching

Laser marking and etching provide a high-precision, non-contact method for marking metals. This technique is ideal for creating permanent and easily readable markings on stainless steel, ensuring product traceability and compliance with industry standards.

Dot Peen Marking

Dot peen marking, or pin marking, utilizes a pneumatically driven pin to create a series of dots on the metal surface. This method is fast, reliable, and well-suited for marking alphanumeric characters, serial numbers, and date codes on food-grade stainless steel.

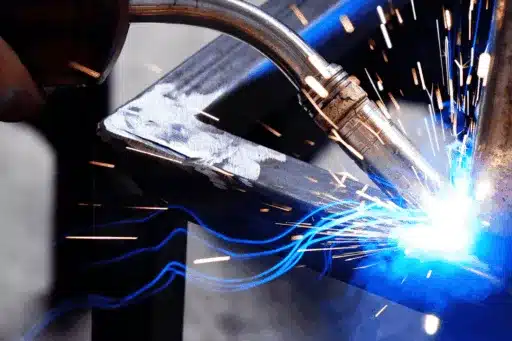

Electrochemical Marking

Electrochemical or electrolytic marking involves using electrical currents and chemical reactions to etch designs onto the metal surface. This method provides a permanent, corrosion-resistant marking solution, making it ideal for the food industry’s stringent requirements.

Get the Sharpest Results in Metal Marking

To ensure optimal performance and longevity in metal marking for the food industry, consider exploring the innovative stainless steel marking solutions offered by TIG Brush. Our marking fluids for steel ensure that your metal markings withstand the rigorous demands of food production environments.

Elevate your metal marking experience with TIG Brush and enhance traceability and safety in food production.