Unveiling the Advantages of Electrochemical Marking on Stainless Steel

21 February 2024

In industrial manufacturing, the rising demand for efficient and precise methods of marking stainless steel has led to the development of innovative technologies. Among these, electrochemical marking has been known for its versatility and durability.

This blog explores the intricacies of electrochemical marking on stainless steel, delving into its applications and shedding light on the benefits it brings to industries seeking permanence in metal markings.

What is Electrochemical Marking?

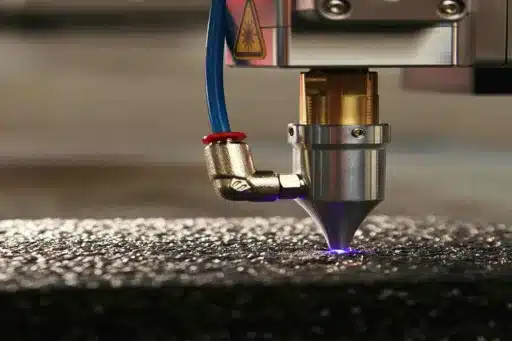

Electrochemical marking, also known as electro-marking or electrolytic marking, is a versatile and efficient method employed for permanently marking metals, particularly stainless steel. This process combines electrical currents and chemical reactions to etch designs, text, or symbols onto the metal surface.

Using custom metal stencils or etching stencils, intricate and precise markings can be achieved on stainless steel, offering a durable and corrosion-resistant solution.

Applications of Electrochemical Marking on Stainless Steel

The applications of electrochemical marking on stainless steel are diverse and impactful. This technique greatly benefits industries such as manufacturing, aerospace, automotive, and electronics. Custom metal stencils play a crucial role in ensuring precise and consistent markings, making electro-marking suitable for applications where accuracy is necessary, such as serial numbers, logos, or part identification.

Benefits of Electrochemical Marking

Affordability and Cost-Effectiveness

One of the primary advantages of electrochemical marking is its cost-effectiveness. Traditional marking methods, such as laser engraving or mechanical engraving, can be expensive due to equipment costs and maintenance.

Electro-marking provides a cost-efficient alternative, requiring minimal equipment and consumables. Additionally, the longevity of the markings ensures a lasting solution, reducing the need for frequent re-marking.

Process Simplicity and Ease of Use

With the use of metal etching stencils, the process becomes straightforward and user-friendly. The operator places the stencil on the metal surface, and the electrochemical reaction does the rest. This simplicity not only reduces the learning curve for operators but also increases overall efficiency in the marking process.

Increased Work Flexibility

Electro-marking offers increased flexibility in terms of marking location and surface orientation. Whether the stainless steel surface is flat, curved, or irregular, electrochemical marking can be applied with precision.

This flexibility is particularly advantageous in industries where parts or products have varying geometries, allowing for a seamless integration of the marking process into diverse manufacturing workflows.

Enhance Your Metal Marking Processes

TIG Brush stands as a trusted ally in the realm of custom metal stencils. Unlock the potential for cost-effective, user-friendly, and versatile metal marking solutions – choose TIG Brush and mark your success with precision.

Discover how our product range can revolutionize your approach to electrochemical marking.