A Guide to Electrochemical Marking and Etching

8 August 2023

Metal parts and machinery undergo marking and etching processes for traceability, branding, and compliance with legal requirements. These processes incorporate logos, QR codes, serial numbers, and vital production details. Among the multitude of marking techniques, electrochemical marking stands out.

This article provides a comprehensive understanding of electrochemical marking, highlighting its significance, applications, methods, and processes.

Understanding Electrochemical Marking

The terms “marking” and “etching” are often used interchangeably when describing metal branding procedures, but they do possess a subtle yet noteworthy distinction.

- When marking, a dark imprint is created on the metal surface without altering its upper layer. Consequently, the only noticeable change resulting from this process is the darkened colour tone of the surface.

- On the other hand, etching involves creating a small incision on the metal surface and removing a portion of the material. As a result, the resulting mark exhibits a light or whitish appearance.

Applications of Electrochemical Marking

Electrochemical marking finds common uses across various industries, including:

- Aerospace Industry: Widely utilized for marking engine parts, bearings, and seals.

- Medical Equipment: Used to apply identification codes, serial numbers, or logos on surgical tools and implants to ensure correct usage and sterilization.

- Tools and manufacturing: Used for marking products such as gauges, hand tools, and cutlery for easier identification, branding, and quality control.

Methods of Electrochemical Marking

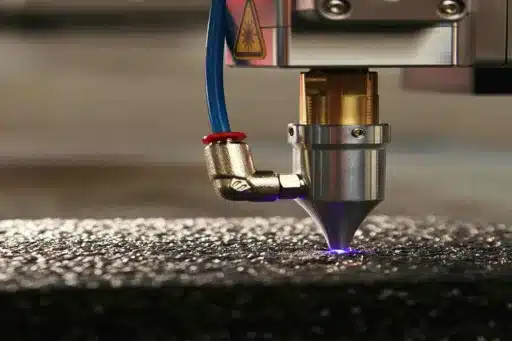

Electrochemical marking and etching are exclusively carried out on conductive metal surfaces.

- A marking head is used with a marking stencil/mask soaked in electrolyte fluid.

- Achieving dark marking and white etching results involves switching between Alternating Current (AC) and Direct Current (DC).

- Electrolytic marking/etching offers greater flexibility, portability, and affordability than other methods.

- Stainless steel surfaces are particularly suitable for electrochemical marking and etching.

- Stainless steel is widely used in industries due to its corrosion resistance and attractive appearance.

- Electrolytic etching and marking provide fast and clear results on stainless steel parts without surface distortion, even on thin metal plates.

Electrochemical Marking Process

Etching and marking with electrochemical machines are remarkably simple and encompass just a few concise stages:

- Printing the stencil/mask for the desired design.

- Preparing the surface by swiftly cleaning it.

- Applying the electrolyte fluid and positioning the stencil.

- Performing the actual marking or etching using the electrode head.

- Neutralising the surface once the marking or etching process is completed.

Get Precision and Durability in Electrochemical Marking With TIG Brush’s Metal-Etching Stencils

Experience Ensitech’s exceptional custom metal stencils for precise metal etching. Handmade in Germany, our durable stencils are specifically designed for etching metal surfaces. With printing calibrated up to 3000 dpi, our stencils guarantee accurate and detailed results.

Backed by over 30 years of craftsmanship, our strict quality control ensures perfection in every stencil. Customers consistently praise our stencils for etching metal, recognising their superiority over competitors.

Elevate your metal etching projects with Ensitech’s top-quality stencils designed specifically for etching metal surfaces. Explore our catalogue today!